How Busway Unlocks Flexibility for Modern Automotive Manufacturing

The Adaptability Problem in Auto Manufacturing

Auto manufacturers across North America are feeling the operational squeeze from multiple factors: smart manufacturing tools and technology, market uncertainty from EV stagnation, and increased levels of mix-model production. Keeping up with the changing manufacturing landscape has automakers leaving Henry Ford’s moving assembly line behind in favor of adopting more flexible manufacturing models.

The shift to electrified, heavily automated manufacturing has dramatically increased the pace of change. EV programs run on much more rapid development cycles than traditional combustion platforms, and each new battery iteration or test station brings unique power demands. Mix-model production line manufacturing for EV, hybrids, and ICEs increases complexity and expenditures.

The evolution of the plant goes beyond sourcing new machinery, integrating AI and automation, and rethinking powertrain assembly layouts. Now automakers need facility infrastructure to adapt to changing electrical needs with speed and efficiency. Downtime costs automakers thousands per minute, meaning even the smallest facility electrical change can cost millions.

Why Traditional Power Systems Fall Short

Traditional electrical systems such as pipe and wire or busduct lock automakers into rigid power layouts and require extensive time and skilled labor to modify. Inflexible power access often leads to the use of extension cords, which can pose safety risks to workers. Furthermore, adding or modifying wiring requires planning and extended periods of downtime, bottlenecking production output.

As plants add more robotics and automation, these limitations are increasingly obstructive. Robots, automated guided vehicles (AGVs), and digital twin technology adjust in real time and often require frequent changes in power location and equipment positioning as models, variants, and processes shift.

In short, robotics and automation demand a power infrastructure that is modular, rapidly adaptable, and designed for reconfiguration. Traditional pipe and wire systems can’t meet these demands without considerable time, labor, and production disruption.

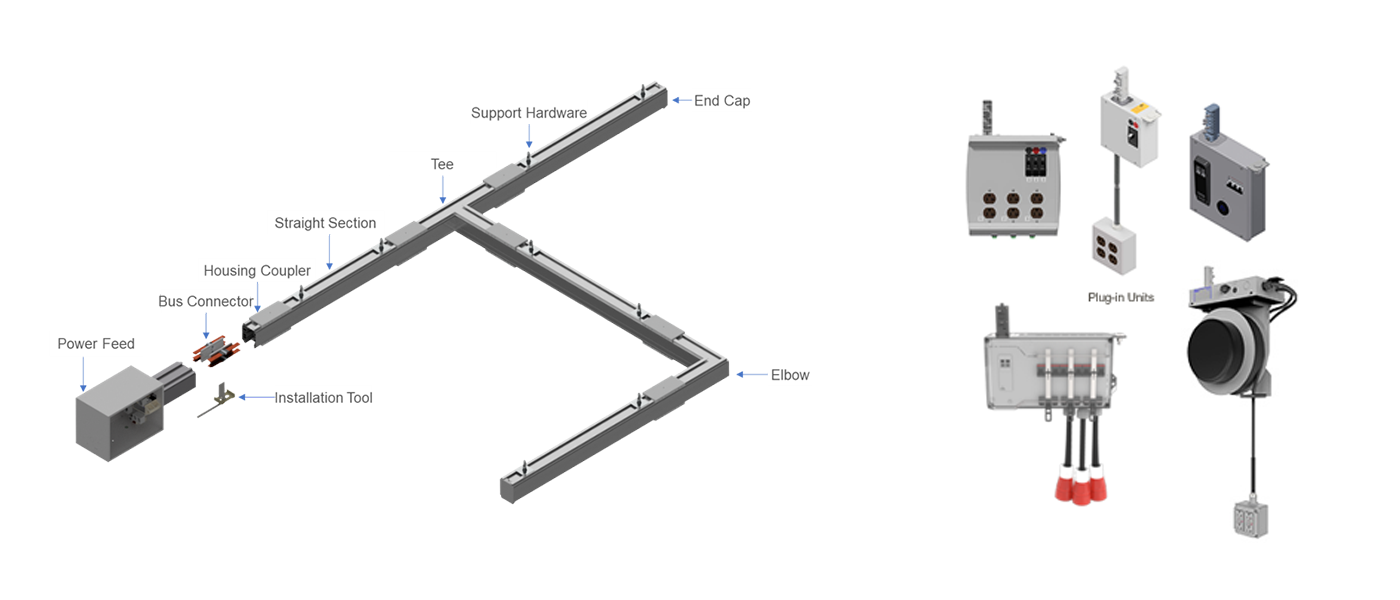

Busway: The Flexible Alternative

Track Busway redefines flexibility with modular, plug‑and‑play power distribution. Instead of installing new conduit runs, busways allow automakers to reposition or add power access points as production layouts and equipment evolve, safely and quickly. That means:

- Faster additions for new equipment

- Minimal disruption during changeovers or work cell moves

- Cleaner installs with local circuit protection

With an open access channel that can be tapped instantly anywhere along the run, electrical changes that previously required weeks of planning and labor can be managed in a fraction of the time.

Real‑World Busway Benefits

Automotive plants utilizing track busway are already seeing improvements in operations. A major automotive manufacturer needed to install a new piece of robotic equipment, and using a stocked busway plug, the team achieved a new power connection in under an hour. Previously, the same task would have required installing additional conduit and breakers, RFQ development, multiple approvals, and resulted in up to a week of lost productivity. By using Starline Track Busway, the automaker reduced downtime and improved operational flexibility.

In addition to speeding line changes, track busway benefits automakers by delivering:

Cost Savings:

Busway reduces the labor needed for installs, requires fewer electricians pulling conduit, and decreases lost production from prolonged outages.

Sustainability:

Busway enables reconfigurability instead of creating waste from rip‑and‑replace. This uses less copper and eliminates unnecessary conduit pulls when modifications are needed, supporting operational sustainability.

Scalability:

Busway’s modular design simplifies line or facility expansions without disrupting surrounding operations. Additional busway sections can be installed onto existing systems by means of joint kits without requiring an additional conduit run to the power feed.

Conclusion

As manufacturing operations evolve toward automation and mixed-model lines, traditional conduit-based power systems box automakers into slow changeovers and costly downtime. Track busway unlocks the flexibility, speed, and reliability modern plants need, especially as EV technology accelerates and robotics use continues to evolve.

To learn more about busway solutions for automotive plants, visit our automotive solutions page, or connect with our team to discuss how busway can help improve flexibility in your facility.