Powering the Future: Meeting Modern Manufacturing Challenges with Scalable Electrical Solutions

The manufacturing landscape is evolving at an unprecedented pace, with adaptability emerging as the new constant. Despite the breathtaking acceleration of technologies like artificial intelligence and data integration, core infrastructure challenges stubbornly persist. As Adrian Sanchez, Director of Commercial and Industrial Sales at Starline, shared during the recent Powering the Future webinar, "We're adopting, we're going fast...but some things will never change. Manufacturers still face the same fundamental challenges."

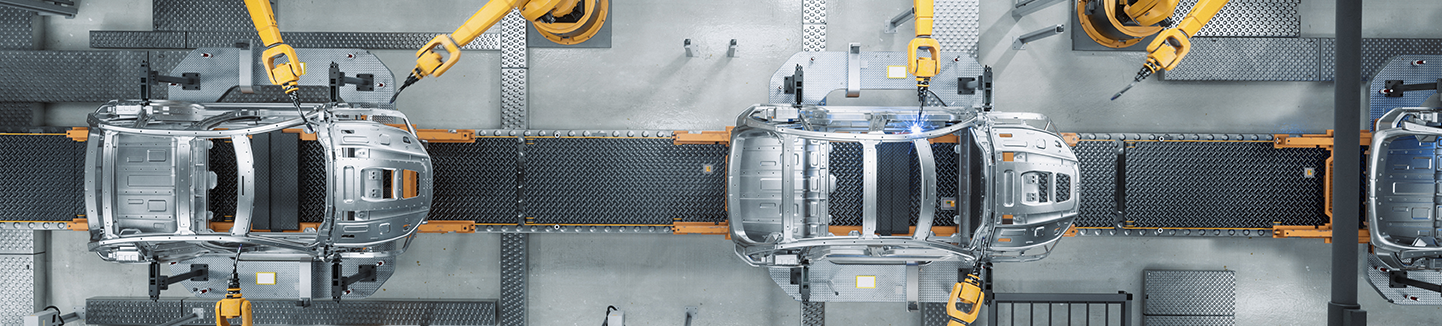

A Manufacturing Sector in Rapid Transformation

Investment trends are telling. According to Sanchez, in North America data center capital expenditures have surpassed those in semiconductors and automotive manufacturing combined. Yet while automation, robotics, and AI redefine what’s possible on production floors, manufacturers are often saddled with century-old electrical infrastructure models like conventional pipe-and-wire systems.

"Conventional electrical distribution methods are like quick fixes for long-term challenges," added Mariam Hamadani, Global Account Manager at Starline. “Maintenance costs add up and flexibility is limited—both critical issues as facilities grow and evolve.”

Adding to the complexity is the emergence of cleanroom, food-grade, and battery production facilities, each demanding more robust, configurable power systems. These sectors require precision, and any misstep in uptime or adaptability can delay production by days, if not weeks.

Meanwhile, pressures from reshoring, supply chain disruptions, and new ESG (Environmental, Social, and Governance) expectations are further accelerating the need for smarter, more scalable infrastructure choices. Flexibility is not just about faster installations; it is increasingly viewed as a competitive advantage.

Persistent Challenges: Cost, Downtime, and Flexibility

When webinar attendees were polled on their biggest electrical infrastructure challenges, the results echoed long-standing concerns:

- Cost and downtime dominated responses (both cited by 27%).

- Technical expertise and workforce availability were also significant hurdles.

As Sanchez noted, "Our manufacturers are businesses. They need to be profitable, and managing operational costs is key." Despite the technology boom, many manufacturers still rely on traditional distribution methods that simply aren't built for today's scale and speed of change. As facilities expand or reconfigure, the inflexibility of hardwired systems leads to costly and time-consuming rewiring projects.

Moreover, the labor required for conventional electrical work often exacerbates workforce shortages—adding delays and increasing total project costs. Facilities that can minimize electrical rework not only stay ahead of production goals but also free up critical resources for innovation. As manufacturers look to the future, scalable and flexible electrical solutions won’t just solve problems—they’ll define industry leaders.

Introducing a Flexible Future: Starline’s Open-Channel Busway

Enter Starline’s open channel busway system—a modern, scalable solution that rewrites the rules for electrical distribution.

With Starline, facilities can create modular power grids suspended overhead. Power access points are easily added, removed, or repositioned by inserting specialized plug-in units directly into the busway. "You can expand it with tees and elbows over time as your layout changes," explained Hamadani.

Scalability is built in: Whether you're starting with a 10ft section or hundreds of feet, expansion is seamless and fast. "We are asked how long can these systems go?" says Sanchez. "And the answer is, how long is the facility?"

Moreover, the open-channel design allows for live insertion, meaning changes can be made with minimal disruption which is a critical feature for manufacturers where downtime can translate directly into lost revenue. The newest Series-S model, offering IP54-rated protection, further enhances its suitability for wet or dusty environments like food and beverage processing, battery plants, and cleanrooms.

Notably, the ability to relocate or add circuits without rewiring opens possibilities for modular manufacturing setups, pop-up production zones, and agile prototyping—essential capabilities in today's competitive environment.

Proven Results: Speed, Safety, and Cost Savings

Real-world case studies illustrate the benefits:

- A Tier I automotive supplier in Texas reconfigured a robotic work cell in under one hour with Starline. Had they used conventional pipe and wire, it would have taken five to six days.

- During the COVID-19 pandemic, a Michigan-based automaker installed a complete power system in just two days, all with construction going on around the installation site, enabling the rapid finish of a new, essential facility.

Additional installations span semiconductor fabrication, battery production, EV charging, and even laboratories and 3D-printing environments. In each case, the common thread is operational resilience built on infrastructure that adapts as fast as the industry demands.

Manufacturers deploying Starline have reported installation time savings of up to 70% compared to traditional methods, alongside significant reductions in downtime during facility reconfiguration projects.

Built for Today and Tomorrow

Starline’s open-channel busway is a great strategy. As manufacturing becomes more digitized and globalized, flexibility is key. From supporting electric forklifts to evolving cleanroom setups, the ability to scale or modify power distribution without rework is transformative.

In addition, Starline's commitment to safety—through features like live insertion grounding and UL857 certification—gives manufacturers the confidence to upgrade their infrastructure without compromising operational integrity.

“Starline was born decades ago in the textile manufacturing industry, has influenced the global proliferation of data centers, and has now come full circle into automotive, semiconductor, and even lab environments,” said Hamadani. "It's really cool to see the product evolve alongside the markets."

Looking forward, as industries embrace electrification, distributed energy resources, and real-time digital control systems, scalable electrical distribution equipment like Starline will become even more vital to operational success.

The Bottom Line

Manufacturers today are asked to grow faster, adapt quicker, and manage tighter margins than ever before. Flexible, scalable electrical infrastructure solutions like Starline’s open-channel busway have become more than a simple necessity—they are an integral part of a manufacturer’s strategy to quickly respond to today’s market needs.

As Sanchez concluded: “It’s important to think beyond just the upfront cost. True cost of ownership—maintenance, downtime, scalability—that’s where the real value lies.” Facilities aiming to future-proof their operations will find flexibility lighting the way forward

This article was originally published on Assemblymag.com August 2025. Republished with permission.

Learn more about how Starline helps manufacturers build for tomorrow by visiting our manufacturing solutions page.